Re-certified ISO9001:2015 ✅

Only “just” out of holiday, and already re-certified in compliance with ISO9001:2015! ✅ Last week, all Provaneers passed the recertification audit very successfully.“An excellent result,” according to the auditor. We […]

Within the world of suppliers, PROVAN distinguishes itself with smaller batches, a wider range and short lead times. PROVAN owes these qualities to a unique production strategy: Quick Response Manufacturing (QRM).

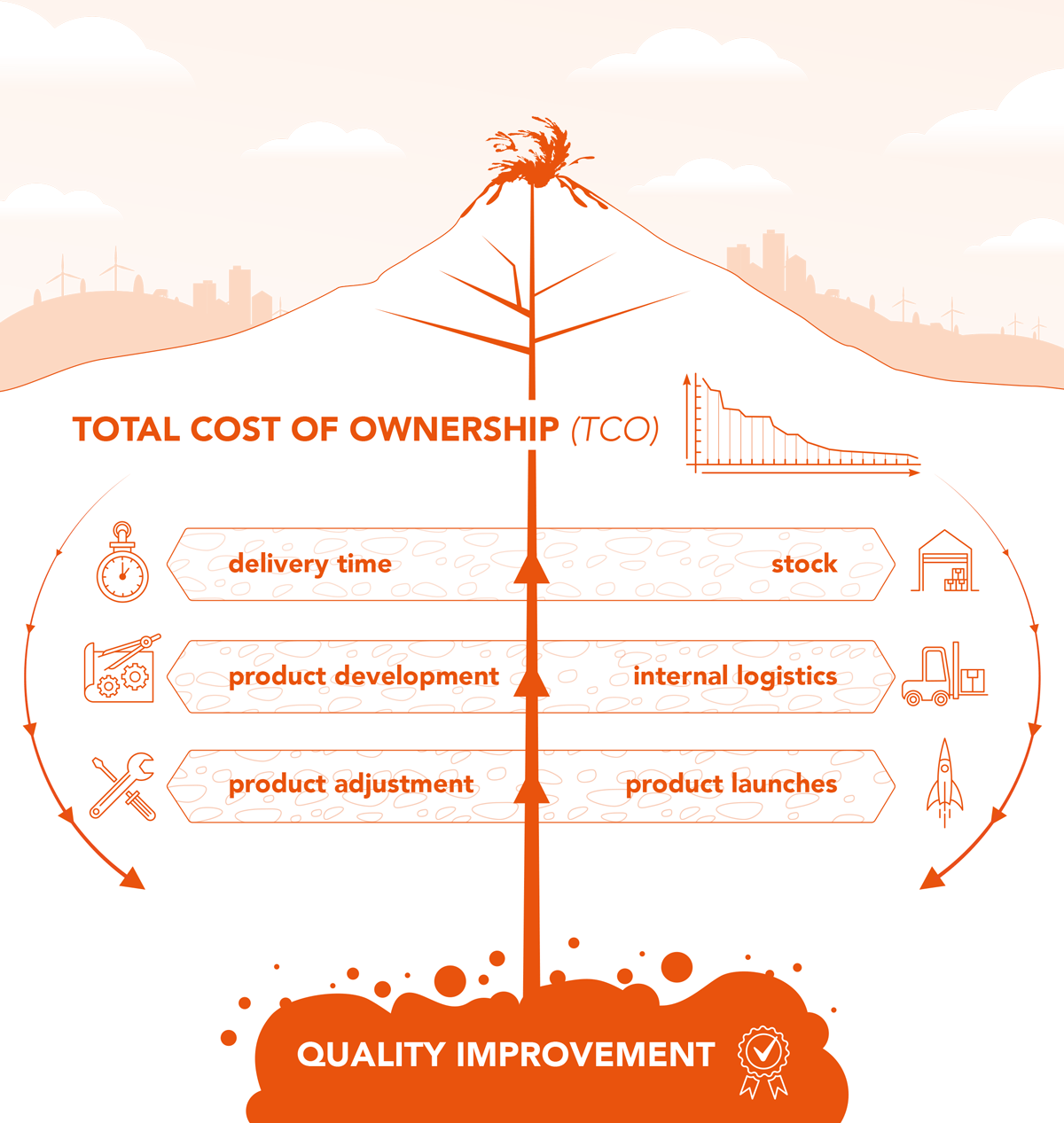

Quick Response Manufacturing is a strategy applied across the entire organisation, with the focus on reducing lead times. We focus on “time” rather than “cost”, with an overall reduction in the Total Cost of Ownership as a result.

In a so-called QRM cell, the machines required to carry out the various operations, are physically grouped together. This eliminates waiting times, and the processing time between the start of production and delivery is reduced.

The lead time of your product, and therefore delivery time, is drastically reduced.

You can respond more quickly to enquiries from your customers and to market developments.

You require less stock, and therefore reduce risk.

The quality of your product always remains of a high standard.

In the long term, QRM results in cost savings and higher turnover – an overall reduction in the TCO.

PROVAN was introduced to QRM by Sirris, the collective centre for the Belgian technology industry. PROVAN has successfully applied the QRM concept since 2012. More and more customers are becoming aware of the benefits of the QRM method.

Furthermore, QRM is a continuous process. In other words, PROVAN works hard every day to improve and simplify its processes. The new POLCA system (Paired-Cell Overlapping Loop of Cards with Authorisation) is an example of this. With POLCA, the work floor is divided into flexible production cells (a production cell groups consecutive operations). This work method results in less disruption, a far better production overview, fewer back orders, reduction of lead time, etc.

What can PROVAN-QRM do for your organisation? We would be happy to introduce you to this system.

From tube, profile and sheet machining to full assembly: PROVAN has the right technology plus the right people!

Within the world of suppliers, PROVAN distinguishes itself with smaller batches, a wider range and short lead times. PROVAN owes these qualities to a unique production strategy: Quick Response Manufacturing (QRM).

Troisdorflaan 22,

Poort Genk 6674

3600 Genk

Pasweg 6b,

3740 Bilzen

Only “just” out of holiday, and already re-certified in compliance with ISO9001:2015! ✅ Last week, all Provaneers passed the recertification audit very successfully.“An excellent result,” according to the auditor. We […]

🌞 The flip-flops and sunglasses have once again been swapped for the trusty welding cap and safety shoes, as the first working week after our summer leave is just about […]

Dear Provaneers, partners and supporters Our welding helmets and safety shoes will be exchanged for sunglasses and flip-flops during our collective holiday from 15 July to 6 August. 🏖 During […]